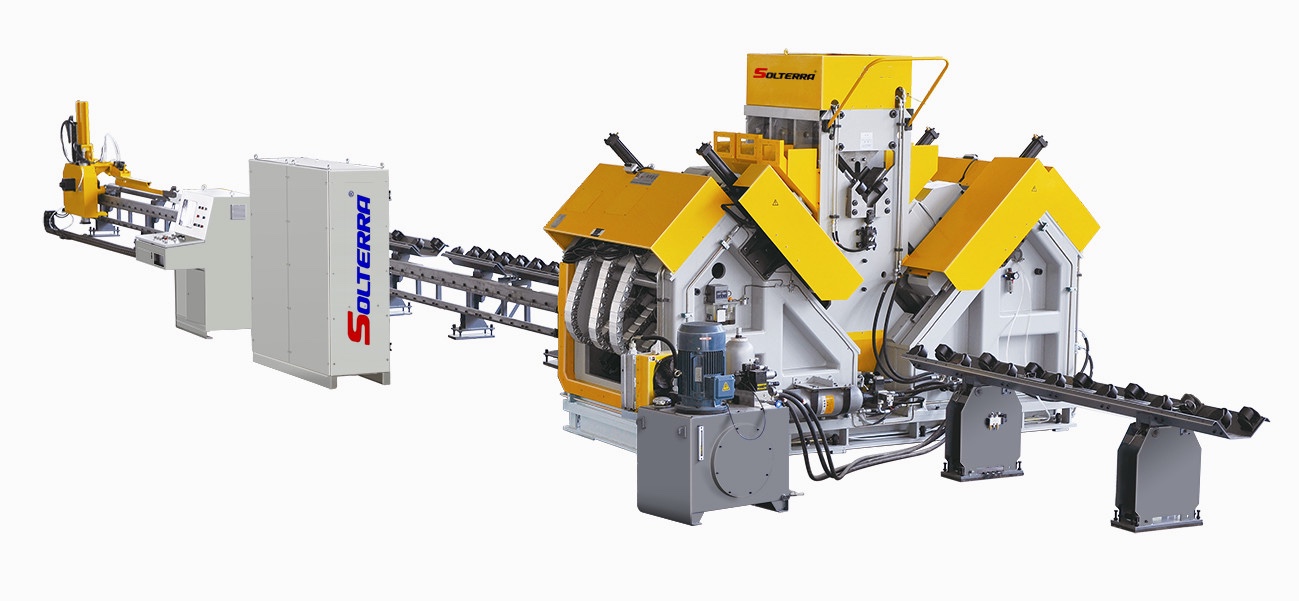

1) This machine is professional automatic equipment for marking and drilling of angle steel.

2) With CNC and servo motor it can get high efficiency and steady precision.

3) The main hydraulic, pneumatic and electrical elements are all imported.

4) Easy program,The Machine can use the automatic data from software directly. Computer with English display and can show work piece figure, easy for operation.

1) Rotation speeds of all spindles are stepless adjustment realized by frequency converter, feeding speed is also stepless adjustment realized by flow control valves(APLH Model is driven by Servo Motor). Working steps of drilling spindles are automatically converted.

2) There is a marking unit in the drilling line.Marking stadia can be preset at will.

3) Circulate Cooling system is applied so as to prolong the life of the drills.

4)Easy programming,only need to input the data of workpiece,including size,hole diameter, stadia accuracy and quantity. Or use the programming data created by lofting software.

Model | ADL3635 |

Function | Drilling & Marking |

Angle Size(mm) | 140×140×10~360×360×35 |

Material | Q235 or Q460 |

Nominal Marking Power(kN) | 1040 |

No. of character group | 1 |

Length of Workpiece(m) | 12/14(optional) |

Character Dimension(mm) | 14×12×19(According to demands of customers) |

No. of character in each character group (piece) | 15 |

Number of drill on each side | 3 |

Range of stadia (mm) | 35-330 |

Main Shaft Speed(r/min) | Max 6000 |

Diameter of drilling hole(mm) | Ф17.5-Ф40 |

Taper of drilling spindle | BT40 |

Drilling Main Axis Travel(mm) | 40—150 |

Number of CNC Axis | 9 |

Angle steel feeding speed(m/min) | 40 |

Programming model | Keyboard enter,USB interface input,Tower lofting software input |

Processing precision | Meeting the requirement of GB/T 2694-2010 |

Total power (kW) | 110 |

Overall Dimension(m) | 30×9.5×3 |

Net Weight (kg) | App.31000 |